A Once in a Blue Moon Experience

Touring the facilities of Blue Origin and Sierra Space

Exploring the intersection of spaceflight history, pop culture, and space art.

Strap in for the exciting continuation of my previous post and join me for not one, but, two factory tours on the grounds of the Kennedy Space Center – Blue Origin’s New Glenn manufacturing facility and Sierra Space’s Dream Chaser processing facility. Along the way, we’ll see an amazing collection of historical space artifacts and contractor models.

Are you new to Creating Space? It’s the NERDSletter that explores the intersection of spaceflight history, pop culture, and space art. You can find this and all other posts at creating-space.art.

Touring Blue Origin and Sierra Space

In the previous edition of Creating Space, I teased about the special tour I went on during this year’s Astronaut Scholarship Foundation’s (ASF) U.S. Astronaut Hall of Fame weekend events in Cocoa Beach, Florida. When I attended last year, we toured the SpaceX Falcon 9 refurbishing facility, which was a spectacular experience. This year topped that, providing double the fun. We were treated to not one, but, two factory tours of so-called ‘New Space’ companies with facilities on the grounds of the Kennedy Space Center – Blue Origin and Sierra Space.

As I mentioned last time, the tour organizers keep the day’s planned location a secret until just before the bus departs. Initially, we were informed of only the first of our destinations, with no indication that there would be a second.

Here’s a photo I shared last time showing our tour group in the bus with all our happy faces after we learned we would be touring the Blue Origin New Glenn rocket manufacturing facility.

Blue Origin Tour

As we approached the Blue Origin facility, just south of the Kennedy Space Center Visitor Complex, the immensity of their operation became apparent. We passed one massive blue and white factory building and pulled up to a second, equally large, building.

Blue Origin’s Florida operations cover 250 acres – a site those at the company refer to as “Rocket Park”.

The area taken up by Rocket Park is over three times the land area occupied by the entire Kennedy Space Center Visitor Complex, including its parking lots and the Apollo Saturn V Center building. Just to drive this home, the Visitor Complex encompasses 70 acres1 and houses the Space Shuttle Atlantis pavilion, a rocket garden with a Saturn IB and seven other rockets, the U.S. Astronaut Hall of Fame® and Heroes & Legends pavilion, the Gateway “new” spacecraft pavilion, back-to-back twin IMAX theaters, several other attraction buildings, a substantial gift shop, a large tour bus loading/unloading area ... and, in the Saturn V Center, an entire Saturn V rocket plus a Command and Service Module, the Apollo 14 Command Module, a full size Lunar Module (LM), a Lunar Rover mockup, and more!

Making A Big Entrance

Inside the Blue Origin factory building, photos were restricted to the front entrance lobby. But, what a lobby it was!

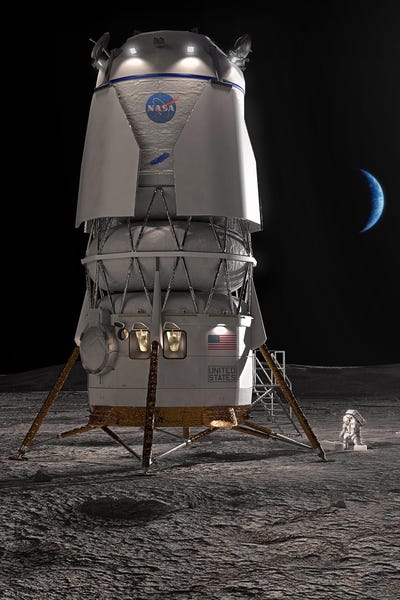

The first thing that struck me when I entered the Blue Origin lobby was a towering full-scale mockup of their Blue Moon Mark 1 (MK1) autonomous cargo transport and lunar lander. Its height reached close to two factory-sized stories, comparing it to the adjacent exposed stairwell.

Elsewhere in the vast lobby, were monuments to Blue Origin’s other signature projects. A giant poster of their latest and largest rocket, New Glenn, adorned one of the walls.

Nearby, a scale model of New Glenn stood like a sentry at the entrance.

A pair of rocket engines, a BE-3U and BE-4, also designed and built by Blue Origin, were proudly displayed against a wall emblazoned with a quote (unattributed, but presumably from Blue Origin founder Jeff Bezos), “It’s this generation’s job to build a road to space”.

Fly Me to the Moon

Being an Apollo Lunar Module fanatic, it was a special treat to see Blue Origin’s next-generation lunar lander mockup. Even though the MK1 is meant to deliver cargo rather than people to the Moon, it wasn’t a stretch for me to equate the experience of seeing this mockup to the early days of Apollo. I imagined it might have been like witnessing, in person, Grumman’s Lunar Module mockup at their Bethpage, New York, facility in the early 1960s.

The design aesthetic of the MK1 contrasts sharply – or maybe I should say smoothly – with that of the Apollo Lunar Module (LM), the last crewed Moon lander, so far to date. As opposed to the angular appearance of the Apollo LM, the contours are mostly curves. The only angles found on the MK1 are the cutouts for the main propellant tanks, and at the top of the vehicle – reminiscent of the Apollo LM Descent stage’s octagonal form. The capsule-shaped tanks, mounted externally, dominate the lower half of the body – which, itself, is covered in gold foil hearkening, again, back to Apollo. The upper half of the vehicle is cylindrical and sports a clean white coating. Additional tanks – for purposes unbeknownst to me, perhaps RCS propellant – hang, covered in gold foil, supported by struts near the top of the lander.

The MK1, being an uncrewed cargo transport, has no windows. Instead, where one would expect windows to be, there is a painted gold feather, which is the symbol Blue Origin has chosen to represent the perfection of flight. The name of the company, itself, represents the “Blue Earth as our beginning point of the venture into space”, according to our tour guide.

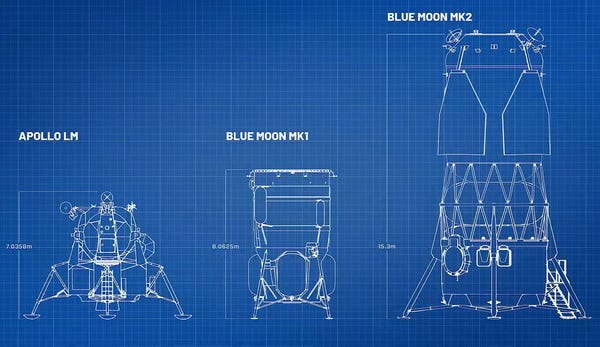

According to Wikipedia, the MK1 reaches 26.4 ft (8.05 m) in height, and its diameter is 10.1 ft (3.08 m). Comparing this with the Apollo Lunar Module, the LM was close to 23 ft (7 m) tall including the rendezvous radar antenna. So, the MK1 is slightly taller than the LM.

Here’s a photo with some former Shuttle astronauts for scale.

This diagram shown during the Spring 2025 Lunar Surface Innovation Consortium provides a good reference for the relative sizes of the Apollo LM, Blue Origin’s MK1 and the planned crew-carrying MK2 reported to stand 50.2 ft (15.3 m) in height.

(NOTE: This diagram states the height of the MK2 as 50.2 ft (15.3 m). Other, more recent sources report the MK2 as standing 52 feet (16 m) tall.)

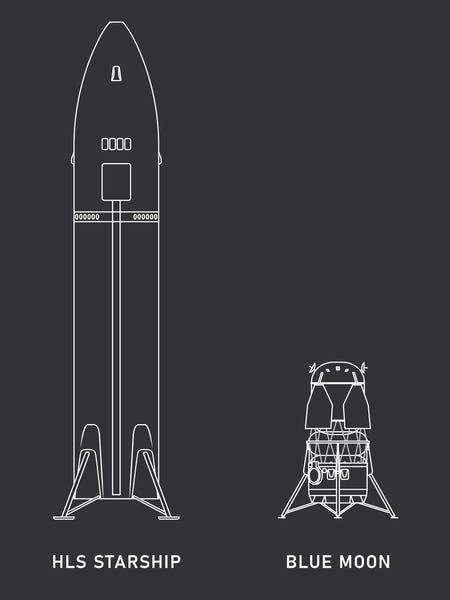

And, in case you were wondering how these compare to SpaceX’s lunar Starship HLS (Human Landing System) proposal, this diagram from 2023 shows its size next to the crew-carrying MK2 from Blue Origin.

As of this writing, there is talk on the web about a possible shrunken version of SpaceX’s monster, but from what I have seen it may still be comparatively tall vs. the height of the MK2.

A Tipping Point

If you will allow me to editorialize for a moment, Blue Origin’s cargo lander, the MK1, seems like a reasonable evolution from the Apollo Lunar Module. Its size is quite comparable. The MK2 appears to stretch the technology, approximately doubling in height relative to the MK1.

Even so, I would note that the landing leg span on both the MK1 and MK2 seem somewhat narrow, given their respective vehicle’s heights.

It seems to me that a fair proportion of the recent uncrewed lunar landing attempts have resulted in vehicles tipping over. Either today’s engineers haven’t studied up on the Apollo Lunar Module, with its wide landing base – which would be difficult for me to believe – or they may be relying on newer, more precise, automated flight controls or some kind of active system for maintaining an upright position. Either way, it appears odd to my Apollo-trained eyes and I can’t help but think there may be some lessons to be learned from history. Of course, the propensity for a vehicle to tip over is primarily driven by the location of its center of mass, which is something I can only guess at from the images and the single mockup I have seen.

I broached the subject with former Space Shuttle astronaut, Rex Walheim, who was present in the Blue Origin lobby, but he didn’t seem eager to indulge my curiosity. Top secret intel, perhaps?

If the Blue Origin landers raise questions about tipping over, SpaceX’s Starship HLS (Human Landing System) lander is downright questionable, in my opinion. Granted, SpaceX has deservedly gained a reputation for turning the previously-thought impossible into routine achievements. But, standing at 172 ft (52.4 m) tall, it baffles me as to how they intend to land their 17-story-tall rocket on the rocky uneven surface of the Moon without it toppling over.

Unless they land it sideways on purpose ...

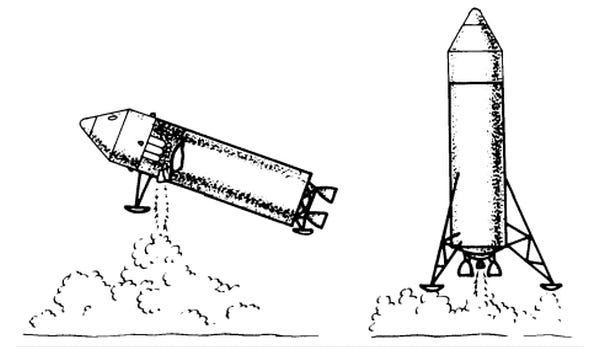

There is historical precedence for such an idea. During the nascent days of the Apollo program development, mission designers were debating the relative merits of two different lunar landing approaches – Direct Ascent and Lunar Orbit Rendezvous. Each one carried unique requirements for the landing vehicle design.

The Direct Ascent mode would have the entire Command and Service Module stack landing tail-first. To accommodate such a landing, an additional landing stage would be added to the bottom, aft of the Service Module. It would contain engines to control the final descent and deployable legs for landing.2

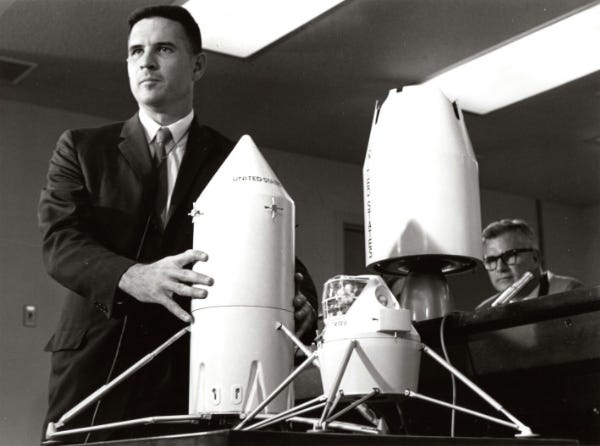

All these stages added up to a very tall – and very massive – structure. You can see in this photograph of the model NASA’s Joe Shea is holding during a 1962 news conference that they recognized the need for a very wide landing footprint – and thus very heavy landing gear.

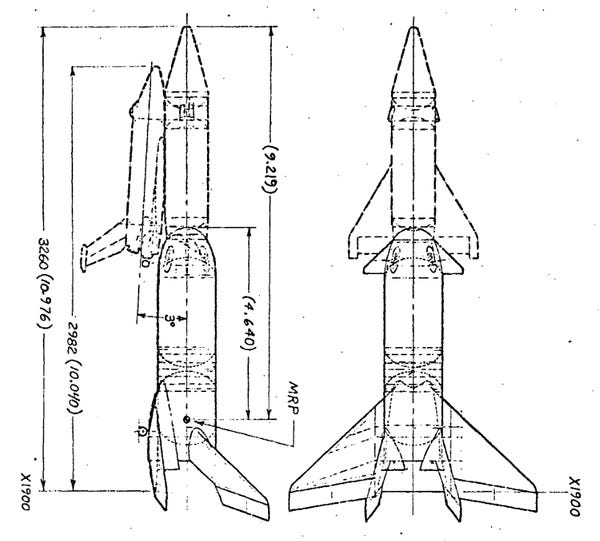

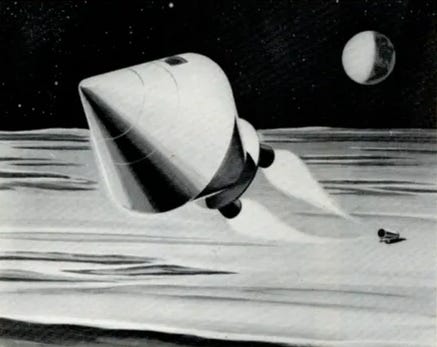

What is perhaps less well known is that NASA had considered landing the vehicle on its side, rather than tail-first. This image shows what a sideways landing might look like, compared with a tail-first landing.3

How then, you may ask, did they intend to ascend off of the Moon when it was time to return home? This illustration by Roy Scarfo, part of a series of illustrations created in 1962 for the New York Times Magazine, shows the return capsule launching almost horizontally from the main landing section.

A Model Display

In addition to the full-scale MK1 mockup and other items in the lobby, there were three unassuming, yet very interesting, climate-monitored display cases tucked under the stairwell behind the MK1 mockup. The average visitor to the Blue Origin factory might easily miss them. I almost overlooked them, myself.

I’m very glad I spotted them, because these were no ordinary displays. They were filled with priceless artifacts and models from the early space age. Given the quality of the items – some of which I recall seeing in past auction catalogs – I think it is safe to assume they are part of the collection of Jeff Bezos, himself.

The first display case contained hardware from various space programs. Jeff is well known for, among other things, his love of the Apollo program. He famously led an expedition that found and recovered, from the Atlantic sea floor, two of the Saturn V first stage F-1 engines use to propel Apollo 11 the first 42 miles (67.6 km) on its historic journey to the Moon.

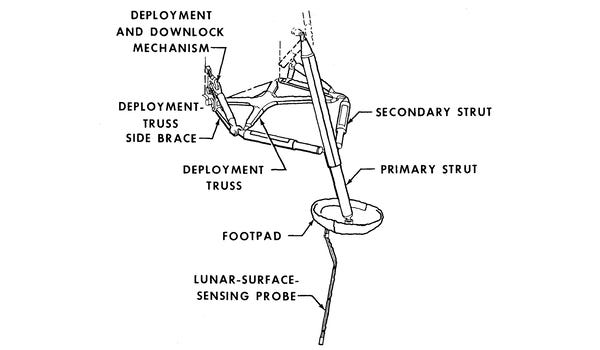

A few of the noteworthy items in this case include a 1962 engineering drop test model of the Apollo Command Module (CM), a full-scale test article of the Lunar Module (LM) Descent stage Landing Leg Deployment Truss Side Brace45, an Apollo Service Module Reaction Control System thruster presented to Max Faget, an Apollo LM Descent engine fuel flow control valve flight spare, and a Saturn V engine duct restraint mount.

Here is a close-up of the LM leg brace and the CM drop test model.

For reference, this diagram shows the installed location of the LM Landing Leg Deployment Truss Side Brace.

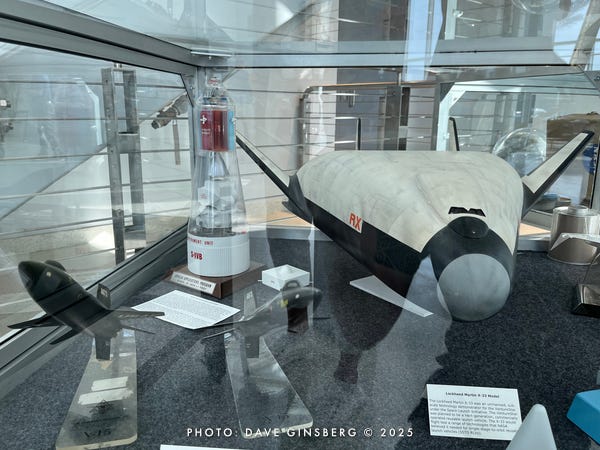

The second display case was dedicated to contractor models. Once again, there were some extraordinary items inside.

The first model that caught my eye looks, at first glance, to be a model of one of the Apollo lunar mission configurations. There it is, tucked behind the large Lockheed Martin X-33 model and a couple of X-15s.

It is actually a set of models displaying concepts proposed for the follow-on Apollo Applications Program (AAP). Readers of Creating Space likely are familiar with Skylab, which was the only flown manifestation of the AAP. This model shows several other ideas for using hardware from the Apollo lunar landing program to extend NASA’s capabilities and perform additional scientific research in space.

The 17-inch (43 cm) tall, 1:48 scale, model is beautifully constructed out of various colors of acrylic with a clear shell which reveals its interior components. In addition to the Lunar Module (LM), the set includes two components that can be swapped out to take the LM’s place inside its housing. One is a combination “LEM Truck Payload and Mission Module”, as it is labeled in red letters typical of models made by the Marshall Space Flight Center Graphic Engineering and Model Studies Branch. The other interchangeable component is identified simply as a “Rack”, presumably containing scientific payloads for use in orbit around either the Earth or the Moon.

I first saw photos of this model when it was up for sale in Bonhams’ 2009 space auction.

I have longed to include it in my own collection ever since. I won’t reveal the exact selling price, but if you add three zeros to the mission number of one of the Apollo lunar landing flights you will be in the ballpark. I didn’t place a bid on this one at the time. But, if you put yourself in a position to bid against Jeff Bezos, would you really have any chance?

That said, it was a thrill to be able to admire the model up close.

If you are a fan of early Space Shuttle concepts, as I am, a notable space plane model in this case will be of interest. The gray model on the blue base is a proposed Trimese concept for a Space Shuttle by General Dynamics and Convair. Originating in 1967, this three-part vehicle combination would boost the central piloted orbiter into Earth orbit. The outer two boosters, also piloted, would separate and extend their swing-wings and be flown back using deployable air-breathing turbofan engines to simultaneous runway landings.

The third, and final, display case contained a mix of contractor models and space-related headgear. A NASA workman’s helmet and an Apollo pressure suit helmet sit in opposite corners of the case. Models of three different space stations fill the middle. And, three contractor models occupy the remaining two corners of the space.

The contractor models are worth a closer look. In one corner is a Marshall Space Flight Center model of a Space Plane cluster consisting of three identical reusable integrated transporters, as defined on the base’s nameplate. This one sold at auction in 2012 for a small number ... followed by a handful of zeros.

On the opposite side of the case sit two other unique contractor models. The tall cylindrical one is a prototype of – I’m guessing – a rocket stage propulsion system. I’m afraid I didn’t quite capture the description on the adjacent label.

The other contractor model is another one I had seen offered at an earlier auction, and in my view is one of the more interesting concepts represented in the trio of display cases.

Here is a clearer photo of the model. According to the auction description, it is an early proposal by Maxime Faget for reusing the Space Shuttle booster engines. In this case, the four main booster engines would be positioned, at launch, aft of the external fuel and oxidizer tanks.

Instead of integrating the main engines into the Orbiter, it appears that a single orbital maneuvering engine was tucked into its aft end. Two additional engines, presumably air-breathing recovery jet engines, are positioned externally on each side of the Orbiter body. As described, the four main engines could be swung into position behind the aft engine compartment of the Orbiter once in Earth orbit. They would remain there through the mission and be brought back for reuse. The description also mentions that the main engines could be jettisoned in case of an abort situation.

The included engineering diagram affixed to the inside of the box lid indicates that the Orbiter and its fuel tank would have been stacked on top of a booster stage, unlike the eventual operational configuration which used a pair of side-mounted solid rocket boosters. An example of such a configuration studied during the development stages of the Space Shuttle is seen in this 1972 diagram of the so-called MSC-040A Orbiter and fly-back booster.

New Glenn Factory Tour

As if the Blue Origin factory lobby didn’t offer enough to capture my imagination, the tour of the actual New Glenn manufacturing facility would prove to be mind-blowing. I’ll get to the tour in a moment, but it is first worth looking at the wide extent to which the company has committed itself to the new space economy.

Blue Origin has several space projects going at the present time. Their New Shepard has been taking people on vertical hops to get brief peeks at the Earth and sky from the edge of the atmosphere since 2019.

New Glenn is their near-Apollo-Saturn-V sized two-stage heavy lift rocket. It stands 321 feet (98 m) tall and is powered by seven reusable BE-4 engines each capable of generating 550,000 lbf (2,450 kN) thrust at sea level6 for a total of 3,850,000 lbf (17,126 kN). The first stage is designed to be recoverable, and they indeed succeeded in safely landing one of their first stages on their second flight, at the time of this writing.

Blue Moon is their entry for landing NASA’s Artemis crew and cargo on the Moon.

Blue Ring is a sort of space tug which is capable of maneuvering, hosting, and deploying spacecraft destined for Earth orbit, the Moon, and interplanetary distances.7

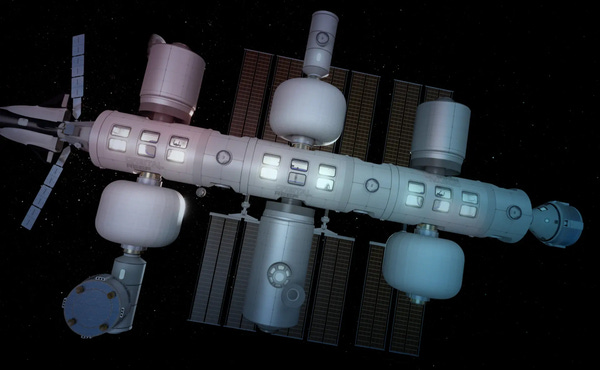

Orbital Reef will be a low Earth orbit space station described on their website as being “architected as a mixed-use business park 250 miles above Earth.” I can say with certainty that I wouldn’t get any useful work done if I had a window seat in that office.

In addition to the headliner projects listed, Blue Origin also offers a wide array of other space solutions including robotics, rovers, instruments, and various spacecraft components.

The two main efforts located at the Kennedy Space Center location are New Glenn and Blue Moon. As much as I would have liked to see the manufacturing facility for the lunar lander, this day’s tour was limited to the New Glenn factory.

Now, on to the tour.

Unfortunately, no photos were permitted inside the actual factory area. Here are a couple photos of the factory interior that have been shared by some major industry and enthusiast publications.

This is an overhead view of the New Glenn first stage booster. The business end – the one with the seven reusable BE-4 engines – is on the far end (right side) in this photo. Four all-flying fins are positioned at the top of the stage (left side of photo), and two long strakes protrude from the base of the booster. Together, they are intended to give the returning reusable stage a degree of cross-range capability.

Here as an overall view of the factory floor. My impressions when first entering the factory, and while walking around, were that it was a very bright and clean environment, and the sound level was relatively subdued compared with my experience in other aircraft factories I have been in.

Tim Dodd (The Everyday Astronaut) posted a video walk-through of the factory last year. His tour guide was Jeff Bezos, himself. This will give you a far better sense of the factory and its contents and processes than I could do through words, alone.

Chasing Dreams

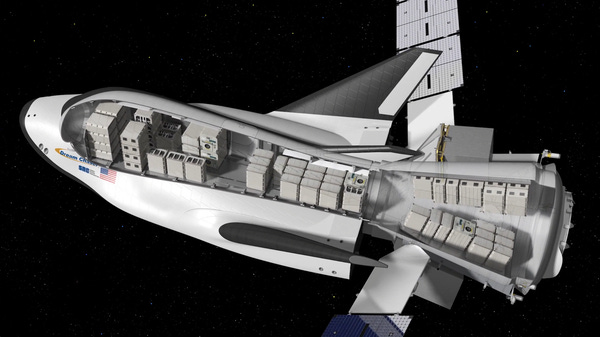

Following our visit to Blue Origin, we were treated to a surprise bonus tour to see Sierra Space’s Dream Chaser, Tenacity – a reusable lifting body vehicle with short folding wings and a low aspect ratio all-flying vertical fin.

I am a big fan of winged spacecraft. Ever since the Space Shuttle stopped flying in 2011, I have felt that we lost a unique, practical, and beautiful mode of space transportation.

The basic airframe of the Dream Chaser can be configured for either crewed transport or cargo. If I understood our guide correctly, both configurations can use the same life support provisions, enabling it to support either human crew or cargo requiring a climate-controlled environment, including live payloads.

A supplementary cargo module can attach to the aft end of the return vehicle, and can be accessed by the crew through a hatch. When berthed to a space station, the module provides a normal cabin environment for astronauts. The supplementary module, referred to by Sierra Space as the Shooting Star module, can be used for cargo disposal since it is designed to burn up safely in the Earth’s atmosphere as Dream Chaser glides gently back onto a runway.8

Development of Dream Chaser began in 2004 as a project of SpaceDev, which was acquired by Sierra Nevada Corporation (SNC) in 2008. In 2021, the program was transferred to Sierra Space, a subsidiary spun off from SNC as an independent company.9

Sierra Space (then Sierra Nevada Corporation) was one of five private companies that were initially awarded development funds from NASA’s Commercial Crew Program in 2010. Later, in 2016, the company was awarded a contract for cargo transport under the Commercial Resupply Services program.

Dream Chaser’s operations are located on the grounds of the Kennedy Space Center inside the Space Systems Processing Facility, which used to be called the Space Station Processing Facility when it was primarily used to support International Space Station operations.

As was the case at Blue Origin, we were not permitted to take photos within the facility. These images published on Sierra Space’s website will provide a peek into what we saw. The spacecraft was located at one end of a long high bay at the back of the building. It sat atop a platform surrounded by support scaffolding, access walkways and stairways, and tooling.

The spacecraft was barely recognizable given the many items obscuring the view and the fact that many of the exterior access panels were removed, revealing much of the interior structure, various tanks, electrical wiring, and other equipment.

The Shooting Star cargo module – itself an impressive and substantially large assembly – was located in a separate high bay.

This cutaway, taken from a SNC video, gives a good sense of how much cargo can be carried and how it might be allocated between the return vehicle and the Shooting Star cargo module.

The Dream Chaser is not an original design, by the way. It is most directly derived from NASA’s HL-20 Personnel Launch System studies in the 1980s and 1990s. The HL-20 was, in turn, modeled from the Soviet Union’s BOR-4 experimental spaceplane, which itself was a one-half scale prototype of the Spiral VTHL (vertical takeoff, horizontal landing) spaceplane.10111213

Other experimental or proposed lifting body spaceplane concepts that can be considered higher up in the Dream Chaser’s family tree include ...

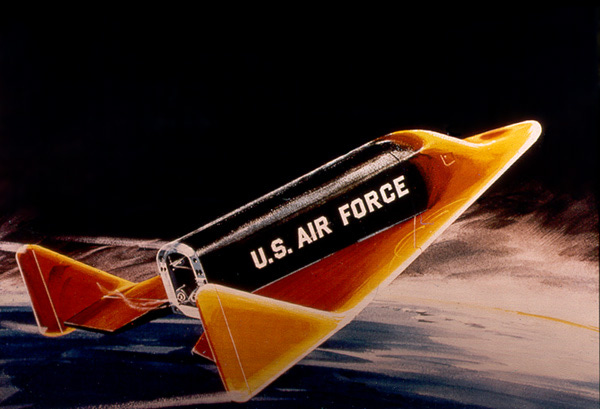

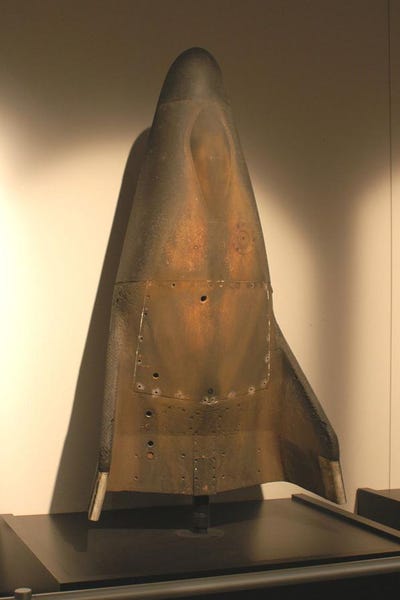

... the X-20 Dyna-Soar (”Dynamic Soarer”), a U.S. Air Force program that spanned from 1957 to 196314 ...

... the Northrop M2-F2 lifting body based on studies at NASA’s Ames and Langley research centers and built by the Northrop Corporation in 196615 ...

... the Northrop M2-F3 lifting body rebuilt from the Northrop M2-F2 after it crashed at the Dryden Flight Research Center in 196716 ...

... the 1966 Northrop HL-10 lifting body research aircraft17 ...

... the Martin X-24A (1969) and X-24B (1973)18 ...

... and the 1966 Martin X-23 PRIME (Precision Reentry Including Maneuvering reEntry) lifting-body re-entry test vehicle.19

So, while Dream Chaser development has been ongoing for over the past twenty years, its roots extend back into the 1950s. Sierra Space has been making progress, recently, towards a projected launch to low Earth orbit in the last quarter of 2026.20 Let’s hope that projection comes true.

Merch of the Month

The Way It Was Imagined: 1962 LEM Giclée Print

This depiction of one of the first concepts for a lunar lander, designed by engineers at NASA’s Langley Research Center in 1962, is a nod to the early Apollo program and the illustrators of that time.

I'm Dave Ginsberg, the artist behind Pixel Planet Pictures and writer of Creating Space.

I am an artist and a creative engineer with a love for teaching and passions for spaceflight, astronomy, and science. My space-inspired art portfolio can be found at pixel-planet-pictures.com.

Do you know fellow Space Geeks who might enjoy Creating Space? Invite them into this space, too!

Did you miss a post? Catch up here.

If you enjoyed this article please hit the ‘Like’ button and feel free to comment.

All images and text copyright © Dave Ginsberg, unless otherwise noted. All rights reserved.

Chariots for Apollo: A History of Manned Lunar Spacecraft, Courtney G Brooks, James M. Grimwood, Loyd S. Swenson, NASA Special Publication-4205, 1979, ch.3

Apollo Lunar Module Landing Gear, William F. Rogers, NASA Manned Spacecraft Center, Houston, Texas (https://ntrs.nasa.gov/api/citations/19730010151/downloads/19730010151.pdf)

Heritage Auctions, Historical, Books, Nature & Science, 2023 May 19 – 20, Space Exploration Signature® Auction #6273, Lot #50134 (https://historical.ha.com/itm/space-exploration/hardware/grumman-apollo-lunar-module-landing-leg-deployment-truss-side-frame-assembly/a/6273-50134.s)

New Glenn, Blue Origin (November 2025) (https://www.blueorigin.com/new-glenn)

New Ring, Blue Origin (November 2025) (https://www.blueorigin.com/blue-ring)

Shooting Star® Cargo Module, Sierra Space, (https://www.sierraspace.com/dream-chaser-spaceplane/shooting-star-cargo-module/)

Dream Chaser, https://en.wikipedia.org/w/index.php?title=Dream_Chaser&oldid=1318438889 (last visited Nov. 12, 2025).

HL-20, NASA Systems Analysis and Concepts Directorate, Vehicle Analysis Branch (https://sacd.larc.nasa.gov/vab/vab-projects/hl-20/)

Dream Chaser, https://en.wikipedia.org/w/index.php?title=Dream_Chaser&oldid=1318438889 (last visited Nov. 15, 2025).

BOR-4, https://en.wikipedia.org/w/index.php?title=BOR-4&oldid=1318684156 (last visited Nov. 15, 2025).

BOR-4, astronautix.com, Mark Wade (http://www.astronautix.com/b/bor-4.html)

Boeing X-20 Dyna-Soar, https://en.wikipedia.org/w/index.php?title=Boeing_X-20_Dyna-Soar&oldid=1318559976 (last visited Nov. 15, 2025).

Northrop M2-F2, https://en.wikipedia.org/w/index.php?title=Northrop_M2-F2&oldid=1304722109 (last visited Nov. 15, 2025).

Northrop M2-F3, https://en.wikipedia.org/w/index.php?title=Northrop_M2-F3&oldid=1307859630 (last visited Nov. 15, 2025).

Northrop HL-10, https://en.wikipedia.org/w/index.php?title=Northrop_HL-10&oldid=1275661691 (last visited Nov. 15, 2025).

Martin Marietta X-24, https://en.wikipedia.org/w/index.php?title=Martin_Marietta_X-24&oldid=1312730191 (last visited Nov. 15, 2025).

Martin X-23 PRIME, https://en.wikipedia.org/w/index.php?title=Martin_X-23_PRIME&oldid=1259425683 (last visited Nov. 15, 2025).

Sierra Space’s Dream Chaser® Spaceplane Successfully Completes Critical Pre-flight Milestones, Sierra Space, November 13, 2025 (https://www.sierraspace.com/press-releases/sierra-spaces-dream-chaser-spaceplane-successfully-completes-critical-pre-flight-milestones/)

Another detailed, fascinating article! Sounds like awesome tours and I'm feeling envious.

Great article